Air suspension centrifugal blower

Product advantages:

Energy-saving and efficient

The high-speed motor direct drive structure, transmission efficiency of close to 100%, and the application of a number of core

technologies, make ACB high-speed centrifugal blower compared with traditional Roots blower, energy saving up to 35%

Low noise, low vibration

The noise at 1m away from the fan is <80 dB, and the vibration during operation is <1mm/s.

100% oil-free

The oil-based bearing and gear growth structure required by the traditional blower is eliminated, and no lubricating oil is required

and no maintenance is required.

Highly integrated and easy to install

Host, electrical, control system is highly integrated, simple structure, small size, light weight, easy to install.

Simple operation, intelligent control

The intelligent control system monitors the operating status of the equipment in real time, and can be controlled remotely to effectively

prevent the overload and damage of the machine.

Through the mobile app, real-time view device operation information warning records, consumables parameters and other data. You can

also remotely start and stop, change the speed and other parameters

Industry application:

Products are mainly used in: environmental protection, textile printing and dyeing, aquaculture, food brewing, biopharmaceutical, powder conveying,

paper making, petrochemical and other industries

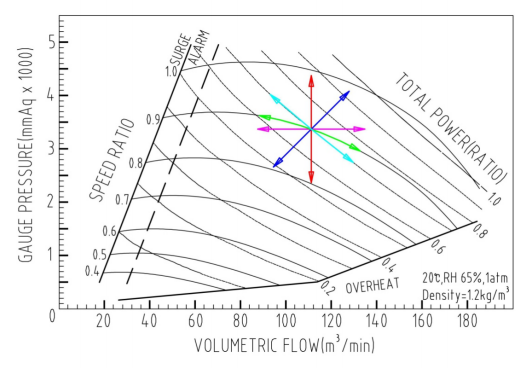

Blower performance curve:

Core technology:

High efficiency three dimensional flow impeller

Using the combination of ternary flow design theory and CFD fluid simulation technology to ensure the efficient performance of the product design:

The use of high-strength aviation aluminum 7075 T651 can be applied to high temperature and high pressure conditions using high-precision five-axis

processing, higher efficiency; The impeller is directly connected with the motor spindle without transmission loss

High speed permanent magnet synchronous motor

The electromagnetic field is optimized to maintain ultra-high efficiency in the full speed range up to 97%, which is significantly better than the traditional

motor; According to the actual load requirements to improve the design, the maximum speed up to 100000rpm;

The use of aviation grade top material, high-end grade permanent magnet, high-performance silicon steel sheet.

Dynamic pressure air suspension bearing

It levitates itself by spinning at high speeds

The latest generation of inconel wave foil bearing improves the bearing stiffness and bearing capacity;

Through structural parameter optimization design and material selection, the problem of bearing failure under high DN value and high working temperature

is solved

on/off test :> 50,000 tests

Intelligent control system

The advanced control system can meet the various process requirements of customers on site

Centrifuge special program, can accurately monitor the system temperature, pressure, flow and other signals, so as to ensure the safe, stable and reliable operation

of the system;

The system supports intelligent cloud control, easy to achieve intelligent control, remote control and other functions, and the operation and maintenance of the

equipment is more convenient and fast:

High speed special inverter

High speed special inverter, the maximum operating frequency can reach 1000Hz;

Advanced space vector pulse width modulation technology can fully realize the driving requirements of high-speed centrifugal blower:

Perfect motor overload protection function

High starting torque, high speed stability accuracy, wide speed range.

Precision filtration system

Filter pressure difference sensor to realize the filter cotton replacement reminder function;

The filtration accuracy is 5um, the initial pressure difference is <100Pa, which can maintain efficient particle interception and low pressure loss, so that the equipment can maintain continuous energy saving;

Long service life, extended maintenance interval time.

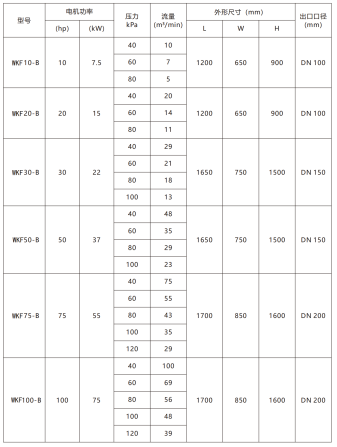

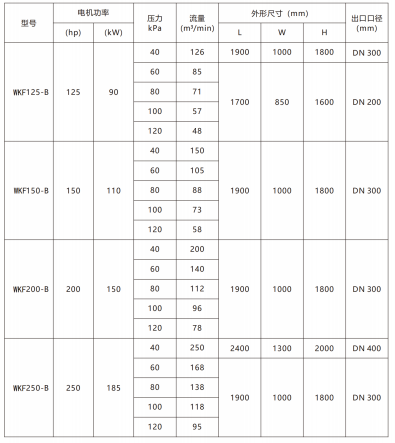

Performance parameter: