Advantages of screw blower/vacuum pump:

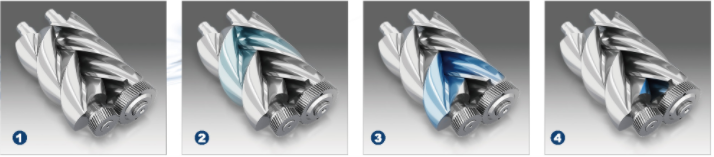

A number of relatively independent sealing cavities are formed between the screw rotor and the cylinder, and the volume is continuously reduced when

the twin screw rotates, continuously changing the air volume and pressure, and achieving the ideal internal compression. The whole compression process

goes through four steps: suction, sealing, compression and exhaust.

Operation principle and energy consumption diagram of screw blower

Suction seal compression exhaust

Screw main engine

The integral casting shell is sufficient to resist deformation and ensure the high-speed and smooth operation

of the rotor. The internal flow channel is specially designed to control the stable air flow and restrain the aero

dynamic noise.

Continuous operation under high pressure and high vacuum only requires single-stage compression without

consumption of cooling water. The rotor is made of high-quality carbon steel, and the surface is equipped with

special PTFE coating, which can play a good anti-corrosion effect, make the rotor have a longer service life, im

prove the sealing and ensure stable gas transmission efficiency.

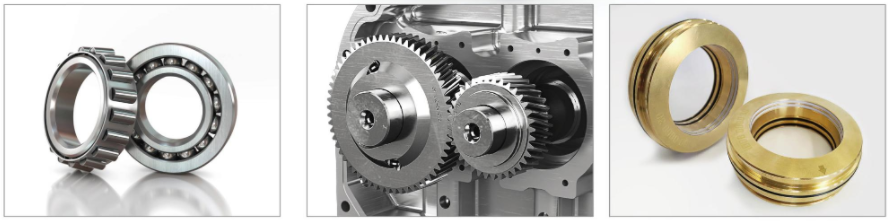

High-strength bearing

Large size, high-strength heavy-duty bearings, even at high speed, its load-bearing performance is also very outstanding, to ensure that

the main engine operation worry-free.

High precision synchronous gear

High strength, high precision alloy steel helical gears for better synchronization, excellent stress absorption and quiet and precise power transfer.

Worry-free sealing

The standard model is an embedded brass labyrinth seal (inflatable labyrinth is optional); Special models with packing seal +Teflon.

Permanent magnet frequency conversion energy saving:

The permanent magnet motor drives the host directly or with a coupling directly, and the transmission efficiency is much higher than that of the belt. The combination of high

efficiency permanent magnet motor and high precision inverter can start smoothly, no impulse current, constant voltage control, constant current control, parameter control,

and the whole process can save energy to a greater extent. Compared with the traditional frequency conversion technology, the permanent magnet motor is more sensitive

and can adjust the speed according to the actual demand of gas more accurately, so it will save energy more than the traditional frequency conversion. The permanent

magnet motor has a smaller volume, which ensures that our unit meets the premise of small and lightweight, the structure and layout are more reasonable, and the maintenance

space is large enough.

Considerate, efficient and reliable overall design:

Permanent magnet frequency conversion energy saving:

The permanent magnet motor drives the host directly or with a coupling directly, and the transmission efficiency is much higher than that of the belt.

The combination of high efficiency permanent magnet motor and high precision inverter can start smoothly, no impulse current, constant voltage

control, constant current control, parameter control, and the whole process can save energy to a greater extent. Compared with the traditional freque

ncy conversion technology, the permanent magnet motor is more sensitive and can adjust the speed according to the actual demand of gas more acc

urately, so it will save energy more than the traditional frequency conversion. The permanent magnet motor has a smaller volume, which ensures that

our unit meets the premise of small and lightweight, the structure and layout are more reasonable, and the maintenance space is large enough.

The transport gas is clean and oil-free

The rotor is not in contact with the rotor, the rotor and the shell, there is no friction, the gear and the bearing are far away from the cylinder, and the

cylinder is clean and oil-free.

No pressure fluctuations and airflow shocks

Continuous and stable operation, no pressure fluctuation, low vibration, low noise.

Low energy consumption

Precise internal compression mechanism, new leak-proof design, smooth airflow channel, energy consumption indicators tend to be perfect.

Higher pressure

The single-stage main engine can reach 2.5bar, and the unique cooling and cooling system does not consume electricity or cooling water.

High reliability and long service life

The rotor, gear and bearing are not affected by impact load, the rotor is made of wear-resistant carbon steel, the surface coating can play a good

anti-corrosionrole, and the service life of the rotor is longer.

Reasonable structure, small and stable body

Repeated optimization of the structure design, simple, reasonable, compact and durable, with good shock and noise reduction effect.

Simple maintenance and low cost

Less wearing parts, less accessories, less consumables, low cost, long maintenance cycle, more economical maintenance.

More intimate control system:

Preferred industrial controller, high resolution color display, years of optimized control software to provide you with a seamless interactive experience

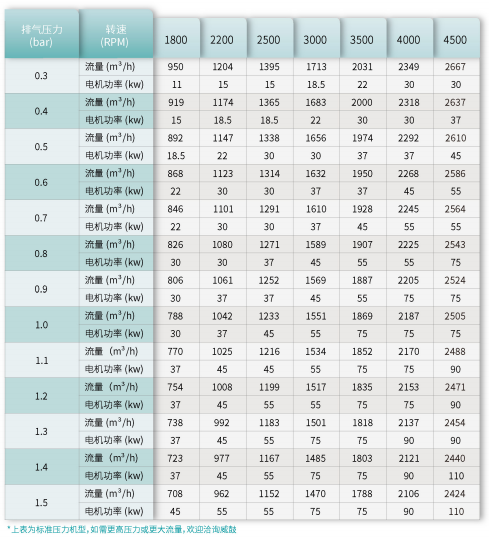

WG series screw blower

Technical specifications range 5.5~250KW

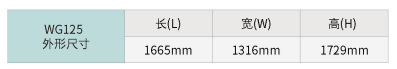

WG125 Technical specification

11----110KW